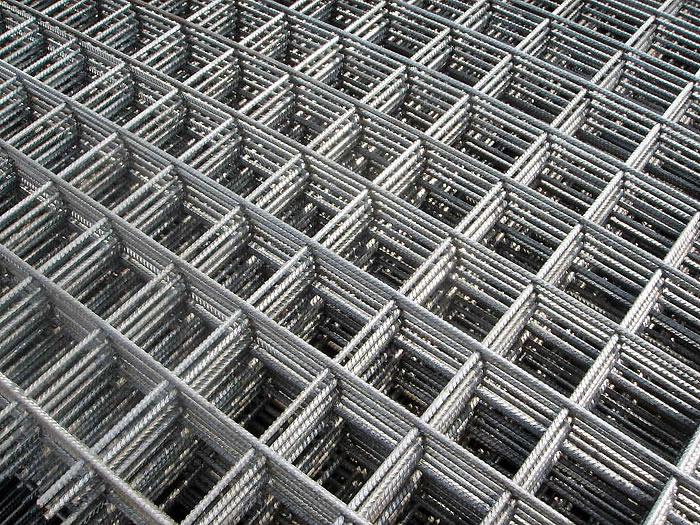

Welded Galvanized Steel Bar Panels for Concrete Reinforcing

Constructional Reinforcing Mesh

Constructional Reinforcing Mesh

This welded fabric can also be used in suspended floor slabs, concrete walls, culverts / drains and composite brick / concrete retaining walls.

GI. Welded Wire Reinforcement Mesh is the irreplaceable concrete reinforcing mesh used in modern construction. It is made of high tensile steel wire spot welded into a square or rectangular mesh mat structure, prefabricated for concrete elements uses. Both electro galv. and hot dipped galvanised treatment available for anti corrosion resistance and long term uses.

Wire / Bar Diameter: 4mm-16mm

Space center of neighbor steel bar

Vertical: 100mm, 150mm, 200mm, 300mm

Horizontal: 100-400mm

Width: 0.5m-3m

Lengt: 2m-6m

Welded steel bar panels are widely used in construction reinforcement, the ground for the tunnels, bridges, highway, airport and wharf, also in construction of wall body.

Features and Benefits

• Economic transport;

• Ease and economy of storage space;

• Reduction of implementation time (high application performance);

• Installation does not require skilled labor;

• Quality ensured by the implementation in factory;

• Reduction of waste and failings.

Steel bar reinforcing mesh,

Galvanizing finish, or

Black wire mesh, non galvanized.

Wire diameter: 10mm,

Mesh: 250mm x 250 mm (8” x8”),

Sheet size: 11.6ft length x 7.6ft width

Structures:

Concrete Reinforcement Welded Mesh Sheet consists of pieces of wire or rebar welded together to form a grid pattern.

The size of the grid pattern is typically 4-inch-by-4-inch up to 8-inch-by-8-inch.

The hole of the grid is in square or rectangular shape:

Rectangular Welded Mesh with wires crossed in a form of a rectangle, and longitudinal wire as the supporting ones

Square opening welded steel mesh with wires crossed in a form of a square, and both longitudinal and transversal wires as supporting ones

Concrete Reinforcing Mesh, in 6 m × 2.4 m Sheet

| Technical Specifications | |||||||

| Longitudinal wire (6 m) | Cross wire (2.4m) | Fabric | Grid Pattern | ||||

| Size (mm) | Pitch (mm) | Area (mm2/m) | Size (mm) | Pitch (mm) | Area (mm2/m) | ||

| 10 | 200 | 393 | 10 | 200 | 393 | Welded steel mesh | Rectangular |

| 10 | 200 | 393 | 8 | 200 | 393 | ||

Welded Wire Reinforcement Mesh, Crimped, Galvanized, Conforming to ASTM 810

Welded Wire Mesh for Reinforcement

Wire form: Crimped / curved

Material: Galvanized mild steel

Quality:

Conforming to

ASTM 810

7½ width (190.5 MM)

Mesh: 67 mm x 25.4 mm

Number of line wire / width: 8

Wire diameter: 2.10 mm line wire x 1.70mm cross wire

Roll length: 165m

Welded Wire Mesh Reinforcement

Wire form: Crimped / curved

Material: Galvanized mild steel

Quality:

Conforming to

ASTM 810

Conforming to

ASTM 810

7½ width (190.5 MM)

Mesh: 67 mm x 25.4 mm

Number of line wire / width: 8

Wire diameter: 2.20 mm line wire x 1.80mm cross wire

Roll length: 160m

Carbon Steel Rebar Welded Cage, especailly used for strengthening concrete in sub marine construction of oil pipes projects. It is made by welding with black steel rods into a cage-shaped steel banding mounted skeleton.

Welded Steel Rebar Mesh Cages

Reinforcing steel bar welded cages are circular mesh pads used in the pre-casting production of pits, covers and tunnels.

Ways to connect the short pile cages together:

A, Combine the main rebar first and then the pile cage, that is to say, butt weld the rebar of 9m length together to 9-27 meters and then use the pilemaster to longer pile cage.

B, Combine the pile cage and then the main rebar, first make the pile cage of 9m or 12m of standard. And then weld the short pile cages to longer pile cages.

Installation of the inner reinforcing bar and double rebar:

To get the double rebar pile cages to improve work efficiency, normally we suggest welding the second bar after the pile cage is formed.

And for the inner reinforcing bar, we supply the rebar bending machine to reinforcing the stirrup. Compare to weld manually, the difference is the rebar ends do not bond together, hence easier to install.

Standard Meshes (4.8m x 2.4m)

| Longitudinal wires / bars | Cross wires / Bars | |||||||

| British Standard Reference | Size mm |

Pitch mm |

Area mm²/m |

Size mm |

Pitch mm |

Area mm²/m |

Kg/m² | Kg/sheet |

| Square Mesh Fabric | ||||||||

| A393 | 10 | 200 | 393 | 10 | 200 | 393 | 6.16 | 70.96 |

| A252 | 8 | 200 | 252 | 8 | 200 | 252 | 3.95 | 45.50 |

| A193 | 7 | 200 | 193 | 7 | 200 | 193 | 3.02 | 34.79 |

| A142 | 6 | 200 | 142 | 6 | 200 | 142 | 2.22 | 25.57 |

| A98 | 5 | 200 | 98 | 5 | 200 | 98 | 1.54 | 17.74 |

| "A" Mesh - Detail of a Standard Sheet | ||||||||

| Structural Mesh Fabric | ||||||||

| B1131 | 12 | 100 | 1131 | 8 | 200 | 252 | 10.90 | 125.57 |

| B785 | 10 | 100 | 785 | 8 | 200 | 252 | 8.14 | 93.77 |

| B503 | 8 | 100 | 503 | 8 | 200 | 252 | 5.93 | 68.31 |

| B385 | 7 | 100 | 385 | 7 | 200 | 193 | 4.53 | 52.19 |

| B283 | 6 | 100 | 283 | 7 | 200 | 193 | 3.73 | 42.97 |

| B196 | 5 | 100 | 196 | 7 | 200 | 193 | 3.05 | 35.14 |

| "B" Mesh - Detail of a Standard Sheet | ||||||||

| Long Mesh Fabric | ||||||||

| C785 | 10 | 100 | 785 | 6 | 400 | 70.8 | 6.72 | 77.41 |

| C636 | 9 | 100 | 636 | 6 | 400 | 70.8 | 5.55 | 63.94 |

| C503 | 8 | 100 | 503 | 6 | 400 | 49.0 | 4.51 | 51.96 |

| C385 | 7 | 100 | 385 | 6 | 400 | 49.0 | 3.58 | 41.24 |

| C283 | 6 | 100 | 283 | 6 | 400 | 49.0 | 2.78 | 32.03 |

| "C" Mesh - Detail of a Standard Sheet | ||||||||

| Wrapping Mesh Fabric | ||||||||

| D49 | 2.5 | 100 | 49 | 2.5 | 100 | 49.0 | 0.77 | 8.87 |

Netting Type for Welded Reinforcement Concrete Mesh for Slabs Production

Detail Design of 150x300 Weld Wire Mesh Net

Welded Iron Steel Wire Mesh Fabric of 5mm, in 960mmx710mm sheet, detail technical reference

- Vinyl Coated Welded Wire Mesh

- Galvanised Welded Mesh

- Stainless Steel Welded Wire Mesh

- Galvanized Mesh Hardware Cloth

- GI. Welded Wire Panel

- Galvanized Square Mesh Cloth

- Welded Reinforcing Mesh Fabric

- Application

- Anti Climbing High Security Fence

- Galv. and PVC Coated Galvanized Chain Link Fence

- Galvanized Steel Security Fence

- Galvanised Welded Wire Fence

- Galvanised and Powder Coated Pool Fencing

- Powder Coated Holland Type Euro Fence

- Temporary Fence

- Perimeter Fence

- Welded Mesh Gridwall Panel

- Wire Mesh Shelving